Before you start, it’s important to check:

- That fence footings do not exceed legally established property lines. If uncertain, refer to real estate agent’s line plot or consult a professional surveyor.

- Local codes for specifications regarding frontage locations, allowable fence heights, etc. A permit may be required.

- With local utility companies for locations of underground cables or pipelines.

Tools You Will Find Useful

- String or Chalk Line and Stakes

- Tape Measure

- Post Hole Digger, Wheelbarrow, Shovel, and Hoe to mix and transport concrete

- Carpenter’s Level

- 1/2″ and 9/16″ Wrench or Crescent Wrench

- Hacksaw or Pipe Cutter

- Fence Stretcher

- Pliers

- Tension Wire Clip (Hoe Ring) Pliers

Installing Master Halco Chain Link Fences

Prepare Fence Layout

STEP 1

Locate your property’s boundary lines. It is recommended that all posts be set approximately 4″ inside the property line so that concrete footings do not encroach onto any adjoining property.

STEP 2

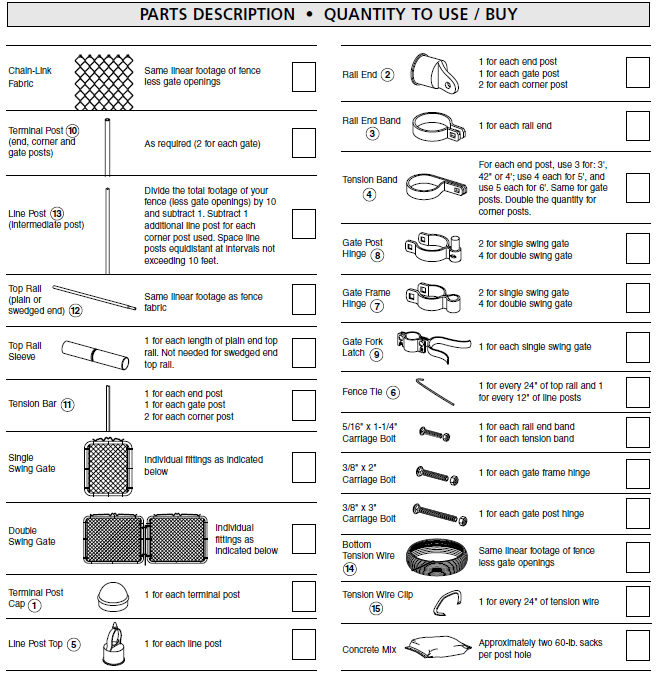

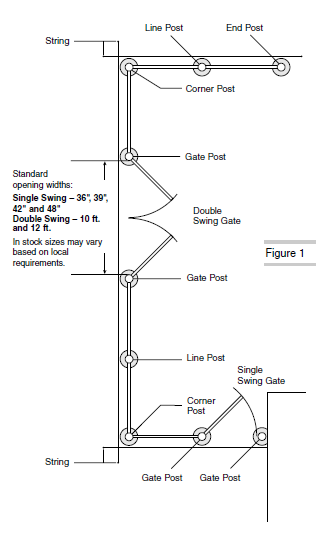

Measure the overall length of your planned fence to determine how many feet of chain link fabric and top rail will be required (Fig. 1).

STEP 3

Mark the location of each terminal post (corner, end, and gate posts are called terminal posts) with a stake.

When determining the positions of gate posts remember that clearance for hinges, latches, etc., is included in the listed opening width of the gate. Therefore, if you ordered a gate for a 36″ opening the post spacing should be exactly 36″, inside post face to inside post face.

Setting Terminal Posts

STEP 1

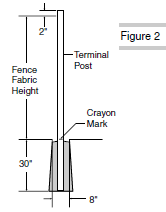

Dig terminal post holes approximately 8″ in diameter and 30″ deep, with sloping sides (Fig. 2). The exact diameter and depth will be determined by

local weather and soil conditions.

STEP 2

With crayon or chalk, mark the ground line on posts. Height, above level ground, of terminal posts will equal the height of the fence fabric plus 2″.

STEP 3

Center the terminal posts in the holes. Make sure the posts are plumb and set at the correct height. (Crayon mark should be at ground level.) Surround posts with concrete in a continuous pour. Trowel finish around posts and slope downward to direct water away.

Locating and Setting Line Posts

STEP 1

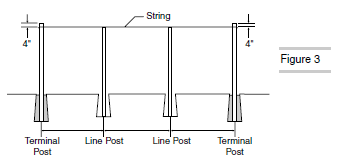

When the terminal post footings have hardened enough to stabilize the posts, stretch a string line taut between terminal posts. The string should be positioned on the outside face of the posts 4″ below the top (Fig. 3). Height, above level ground, of line posts will equal the height of the fabric minus 2″.

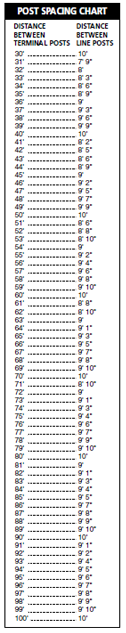

STEP 2

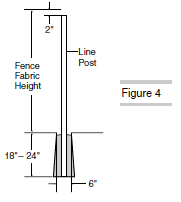

Measure the distance between terminal posts and refer to Post Spacing Chart to determine the distance between line posts. Dig line post holes 6″

wide and 18″ to 24″ deep, with sloping sides (Fig. 4). Center the line posts in the holes. Make sure the posts are plumb, aligned with the centers

of terminal posts, and set at the correct height. Surround posts with concrete in a continuous pour. Trowel finish around posts and slope downward to direct water away.

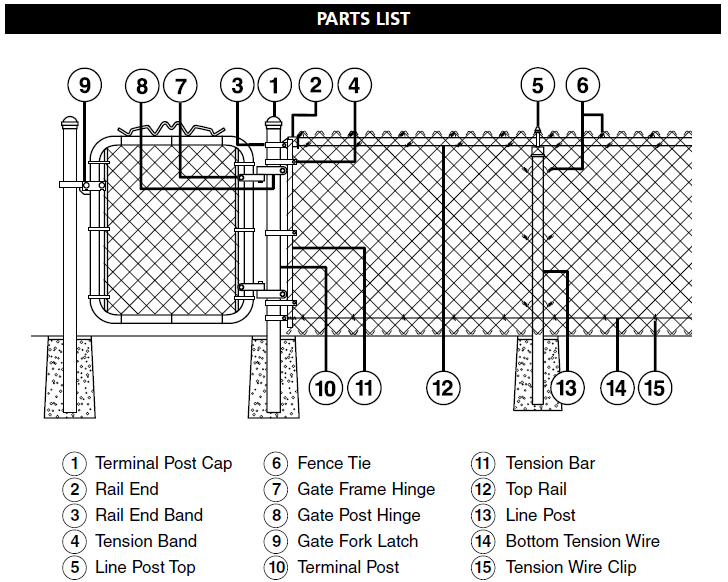

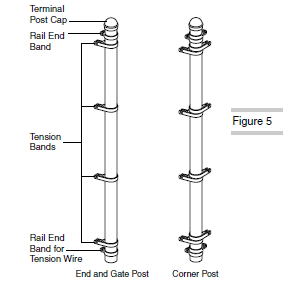

Adding Fittings to Terminal Posts

STEP 1

After concrete footings have been allowed to sufficiently harden, slip the rail end bands and tension bands onto the terminal posts. (Refer to

parts list for the description and quantity of fittings that are required for various post types and heights.) The long flat surface of the tension band

should face toward the outside of the fence (Fig 5).

NOTE: Take care not to spread or distort the fittings.

STEP 2

Apply all terminal post caps.

Terraced Ground

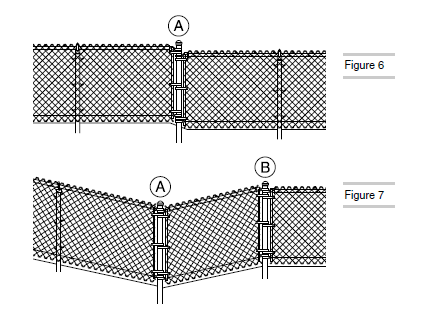

Corner post assembly is used at point A to allow fabric to follow terraced contour of ground (Fig. 6).

Very Uneven Ground

Corner post assembly is used at points A and B when ground rises or drops more than 15″ per 100 linear feet (Fig. 7).

Installing Top Rails

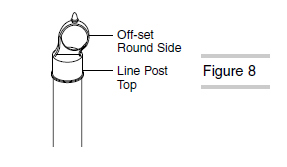

STEP 1

Place line post top on the top of each line post. The off-set round side should be toward the outside of the fence (Fig. 8).

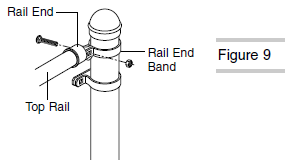

STEP 2

Insert one length of top rail through the line post top closest to a terminal post. Slip rail end onto the end of the top rail and attach it to a terminal post by using a rail end band. Secure by using a 5/16″ x 1-1/4″ carriage bolt with the head to the outside of the fence (Fig. 9).

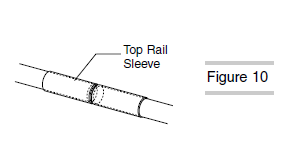

STEP 3

Continue by forcing lengths of swedge end top rail together through the line post tops. (If swedge end top rail is not used, join lengths together with top rail sleeves.) (Fig. 10)

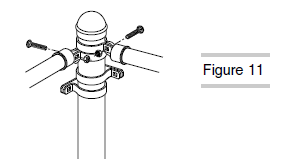

STEP 4

Upon reaching the next terminal post, measure carefully and cut the top rail to fit tightly between the last length of top rail and the rail end. Fasten rail end to rail end band on the terminal post. Secure in place with a 5/16″ x 1-1/4″ carriage bolt (Fig. 11).

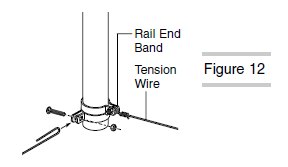

Adding Tension Wire (Optional)

Wrap tension wire once around bottom rail end band carriage bolt. Using pliers, twist several times to secure (Fig. 12). Tension wire should run along the same side of the posts as the fabric. Apply tension wire clips no more than 24″ apart, or as needed for securing the wire to the chain-link fabric.

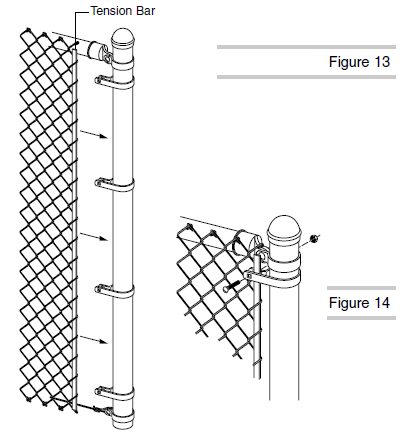

Hanging Fence Fabric

STEP 1

Starting at a terminal post, unroll chain-link fabric on the ground along the outside of the fence line to the next terminal post. Slide a tension bar through the first row of chain-link diamonds. Fasten evenly spaced tension bands (already on the post) to the tension bar, fabric combination using 5/16″ x 1-1/4″ carriage bolts with heads to the outside of the fence (Figs. 13 & 14).

STEP 2

Walk along the fabric and stand it up against the fence frame, taking out the slack as you go. Loosely attach fabric to top rail with a few fence ties to hold it in place. Separate enough fabric from the roll to span the opening between the terminal posts.

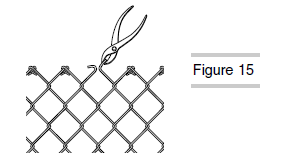

TO REMOVE EXCESS FABRIC:

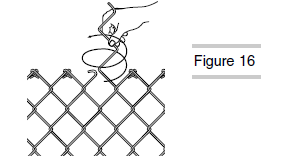

Remove the excess fabric with pliers by opening the top and bottom loops (knuckles) of a single strand of wire at the desired point of separation. Unwind the strand up through the links until the fabric comes apart (Figs. 15 & 16).

TO SPLICE SECTIONS OF FABRIC:

Splice sections of chain-link fabric together using a single strand of wire, removed from the end of the fabric. Join the two sections by winding the loose strand down, corkscrew style, through the end links. Join and tighten the knuckles at top and bottom to secure.

Note: Before sections can be spliced, a second strand may have to be removed to provide a proper mesh.

Stretching Fence Fabric

STEP 1

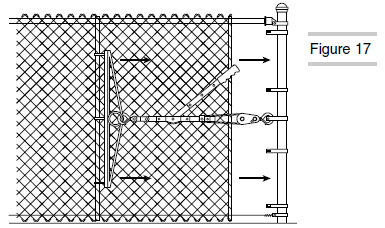

Temporarily insert a tension bar about 3 feet inside the unattached end of fabric. Securely fasten one end of the fence stretcher to the tension bar and the other end to the terminal post (Fig. 17). Stretch the fabric. The correct fabric tension should allow a slight amount of give when squeezed by hand. Remove the temporary tension bar.

STEP 2

Adjust the fabric to exact length by adding or removing wire as shown in figures 15 and 16. Insert a tension bar at the end of the fabric and connect to tension bands on terminal post.

HILLSIDE STRETCH — BIAS CUTTING: (IF NECESSARY)

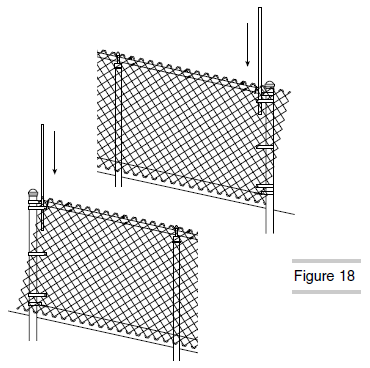

If the top of the chain-link fabric does not create a right angle to the terminal post, the fabric must be cut on a bias so that the tension bar can slide into the fabric at the proper angle. Pull the chain-link fabric until the top or bottom, whichever is shortest, reaches the terminal post. The other corner of the fabric will extend past the terminal post. Insert the tension bar at an angle through the fabric parallel to the terminal post (Fig. 18). Remove the excess wire by cutting the strands that form the diamond at the tension bar leaving them long enough to bend over the bar. Do not cut every wire. The number of wires cut depends on the degree of slope and the height of the fence.

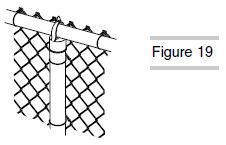

Installing Fence Ties

Fasten the fabric securely with fence ties spaced approximately 24″ apart along the top rail and 12″ apart on each line post (Fig 19). Finally, securely tighten nuts on all rail end bands and tension bands.

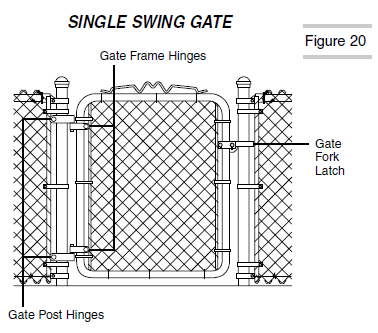

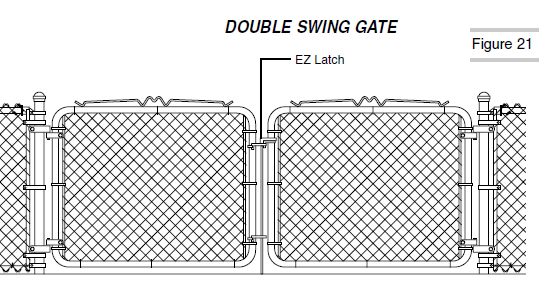

Hanging the Gate

A similar installation procedure is used on both single swing and double swing gates (Figs. 20 & 21).

STEP 1

Apply gate post hinges to gate post approximately 8″ from the top and bottom of the gate post with the top hinge pin pointing down and the bottom

hinge pin pointing up. This will prevent the gate from being removed and/or from dropping off. Tighten all bolts securely.

STEP 2

Apply gate frame hinges to gate frame. Loosely fasten bolts so they can be easily adjusted on the gate frame. Hang gate(s) in place so that the bottom of the gate has approximately 2″ of ground clearance. Tighten the bolts on the bottom frame hinge first, then adjust and tighten the bolts securely at the top.

STEP 3

Position gate fork latch at a convenient height. Tighten all bolts securely.

Note: Adjust EZ Latch Assembly on the double swing gate to the correct height and tighten all bolts securely (Fig. 21).